With 50 years of equipment providing history behind them, HANYANG INDUSTRY (www.hycne.com) has continued to develop its expertise in design, engineering and the manufacture of equipment for oil refinery plants. The company has earned a reputation in not only their local but also global plant supply markets. In this article, HANYANG INUDSTRY shares their experience in how CAE technology has been adopted into all aspects of their product development cycle.

CAE Adoption for Effective Design Validation

HANYANG INDUSTRY came across CAE technology whilst searching for an effective design validation solution. ŌĆ£We realized that designing based on experience as before was very limited. Firstly, modern equipment structures have become very complicated in so much as we have no choice now but to consider many parameters during the design process, such as pressure, temperature, chemical reaction, etc. Secondly, requirements on safety and quality have risen to a new level and so calculating the allowable stress and strain is no longer enough. We want to perform detailed finite element analysis to calculate tensile strength and yield strength for each safety factor valueŌĆØ Mr. Mo, head of R&D department explained in their reasons for adopting CAE solutions into their everyday designs.

Another important reason to adopt CAE is to enhance the in-house technical strengths of our company. ŌĆ£In the past, we only carried out simple strength calculations. For more complex analyses such as structural and heat flow analyses, we relied on outsourcing to external companies. Gradually, we noticed problems in this working process. Firstly, since we could not practice FEA analysis in our team, it was very difficult to judge the accuracy of results data received from our outsourcing companies. We felt it could be a long-term threat to the technical strength of our R&D team. Secondly, the full scale equipment exceeds 100m, which makes outsourcing very costly - both in time and moneyŌĆØ Mr. Park from R&D department explained the difficult decision that the team had made to adopt CAE regardless of limited in-house technology. ŌĆ£Our thinking was very simple. We build complicated products, and there was no way to skip sophisticated structural and fluid analyses. By developing CAE data and technical know-how, we can bring the technical strengths of our R&D team to a new level. Therefore, it was something worth doingŌĆ£

Build an Effective Process for Structural and CFD Analyses

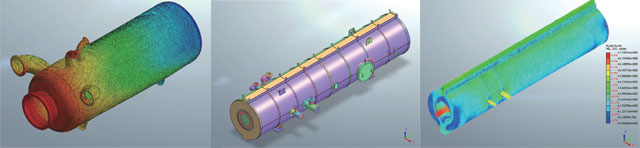

Without the in-house experience of CAE practices, selecting comprehensive but easy-to-learn software is the first step to build an effective CAE process in the team. ŌĆ£We compared several software packages. It was obvious to us that midas NFX was the best choice after many considerations of product capability, price and support quality. ŌĆ£ŌĆ£We purchased midas NFX in October 2013, and were already able to use it properly in projects in January 2014, showing how fast the software can be learned and implemented. After that, midas NFX and midas NFX CFD were used to carry out structural and CFD analyses in 4 projects on more than 10 structural items.ŌĆØ Mr. Mo explained the quick adoption of midas NFX in his teamŌĆÖs design process.

In HANYANG INDUSTRY, FEA analysis is used to investigate nozzle stress under pressure and high temperature. It is also used to evaluate the strength of pipes and tubes under high pressure. Through CFD analysis we are able to predict low temperature corrosion due to toxic gases produced from the industrial process. Also we can investigate the deformation of chimney structures under wind loads.

ŌĆ£We struggled through the early stages of trial and error and also confronted difficulties in selecting proper input values and interpreting analysis result, but all in all this helped our team to face these problems one by one and build onto the analysis process.ŌĆØ

ŌĆ£FE models of our large scale products always contain a large number of meshes. Therefore it is time consuming for analyses and modifications. Furthermore, although the model size is large, and thickness is very small, it is not the easiest condition to create meshes in. To match the 2-3 month design cycle, we needed to get the most useful analysis results in the shortest time.ŌĆØ Mr. Park explained the challenges and struggles. ŌĆ£Difficult as it was, we finally built a satisfying CAE process with MIDAS consistently providing us with valuable product and technical support to help us achieve our goals.ŌĆØ

Enhanced Technology and Global Competitiveness

Besides technical strength, our sales orders also increased after adopting CAE technology into our design process. ŌĆ£Since we are fabricating highly customizable products, the requirements of our customers are constantly changing before the delivery. Therefore, we usually have to redesign and re-evaluate the product several times. The fact that we can perform FEA analysis in-house instead of depending on outsourcing helps us greatly to save on communication time and consulting feesŌĆØ

ŌĆ£We consider CAE technology as one of the most important strategic factors for HANYANG INDUSTRY to compete in the global as well as native market. We know that CAE technology has not yet been widely used in equipment manufacturing industries except for major EPC companies and this creates an opportunity for us. By speeding up our product-development-cycle through using CAE technology, we can deliver our products in a shorter time with more competitive prices. We are hiring dedicated engineers as we will build a CAE team this year.ŌĆØ Mr. Mo Explained HANYANG INDUSTRYŌĆÖs vision on CAE technology.

|