Established in 1986, YUNSUNG F&C CO. LTD has developed a successful business over many years. It designs, engineers and manufactures vessels for food processing and bio-pharmaceutical plants. As a new adopter of CAE technology, YUNSUNG F&C was able to optimize the quality evaluation process in terms of speed and result accuracy. This positive result gives YUNSUNG F&C the confidence to bring their design standards to a whole new level in the marketplace.

CAE Adoption for Comprehensive Product Evaluation and Customer Persuasion

As an experienced vessel manufacturer, YUNSUNG F&C understands the urgency in investigating and solving vessel problems as soon as any issues occur. ÔÇťA broken vessel holding flammable chemicals may lead to a catastrophe in no time. Therefore, it is our first priority to sort the problems out.ÔÇŁ

Hanwon Lee, the senior engineer of the R&D department explained YUNSUNG F&CÔÇÖs consideration before adopting a CAE solution, ÔÇťIn YUNSUNG F&C as in many other vessel manufacturing organizations, many design decisions and solutions were based on previous experience and the engineering teams judgement. However, we gradually saw the necessity to use CAE solutions. Firstly, with CAE methods we could analyze the product from various angles and get accurate results in a relatively short timeframe. Having a comprehensive understanding of the structure could give us more confidence than designing purely based on ÔÇśfeelingsÔÇÖ. Secondly, vessel buyers are more selective these days, and we believe that detailed documents will give buyers a better impression of our company and products.ÔÇŁ

At first YUNSUNG F&C tried to use outsourcing CAE services. After 3-4 times, the company decided to develop its own in-house CAE process since, ÔÇťEngineers complained about the misunderstandingÔÇÖs occurring during communications with outsourcing companies. We couldnÔÇÖt get the correct results the first time, so we had to analyze the structure again, which exceeded our budget, and from then onwards we decided to invest in our own in-house CAE software and manpowerÔÇŁ

ÔÇťAfter comparing the features, prices, interfaces and technical support of various CAE packages, we decided to invest in midas NFX. midas NFX provided us with first class accuracy compared to other relatively famous programs and for the same level of analysis capacity, the price was much more accessible to us. We were especially impressed by the NFX teamÔÇÖs quick feedback to any technical queries that we had,ÔÇŁ Explained Mr. Lee.

Effective CFD Analysis with midas NFX

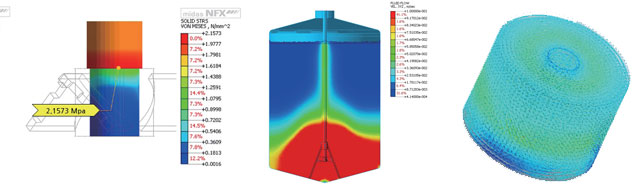

After being adopted into our everyday processes, midas NFX has been used in the design project of mixing vessels. ÔÇťWe use CFD analyses to predict the behaviors of driving and revolving parts during mixing operations; to predict a vesselÔÇÖs vibrations according to different rotation rates, and to calculate the content materialÔÇÖs velocity distribution during the mixing process. Also through structural analysis, we were able to optimize the thickness of the vessel according to its fluid viscosity and to calculate loads on the impeller.ÔÇŁ

Amongst other features of midas NFX, Mr. Lee especially recommended MRF (Multi-Referential Frame) which reduced analysis time significantly when analyzing revolving structures. ÔÇťThe MRF function enables us to perform quick analysis by assigning a relative speed to the structure without actually creating moving meshes. Also temperatures calculated from CFD analysis can be directly used in the structural analysis to calculate stresses and to detect critical points. With advanced CFD and thermal analysis provided in midas NFX, we were able to analyze products in detail and extract useful informationÔÇŁ

ÔÇťWe also received good feedback from our customers. They liked the visualized vessel analysis reports that we provided, and they thought this effort showed YUNSUNG F&CÔÇÖs technical strengths and goodwill.ÔÇŁ

Future Plans for Establishing Design Standards through CAE

Despite being a beginner with CAE solutions, YUNSUNG F&C finds that the future is very bright when it comes to using CAE technology in the equipment manufacturing sector. ÔÇťBeing a beginner of CAE, we still have lots to learn, and some basic problems are as simple as assigning correct boundary conditions. However we see massive potential in CAE. Just as generalization CAD tools a decade ago, CAE technology is being adopted in more and more manufacturing companies now and so YUNSUNG F&C is working relentlessly to build up our own process before this day comes.ÔÇŁ

ÔÇťOur current plan is to make a ÔÇťVessel Design Standard ManualÔÇŁ, which will combine our accumulated engineering know-how and the newly adopted CAE methods. This process will assist us in looking forward to developing a methodology that will guide us to provide consistent and great quality designs.ÔÇŁ

|